Terminal Device for Monkey Bars

This project aimed to design, develop, and test a prosthetic terminal device that allows children with UL differences to safely use monkey bars.

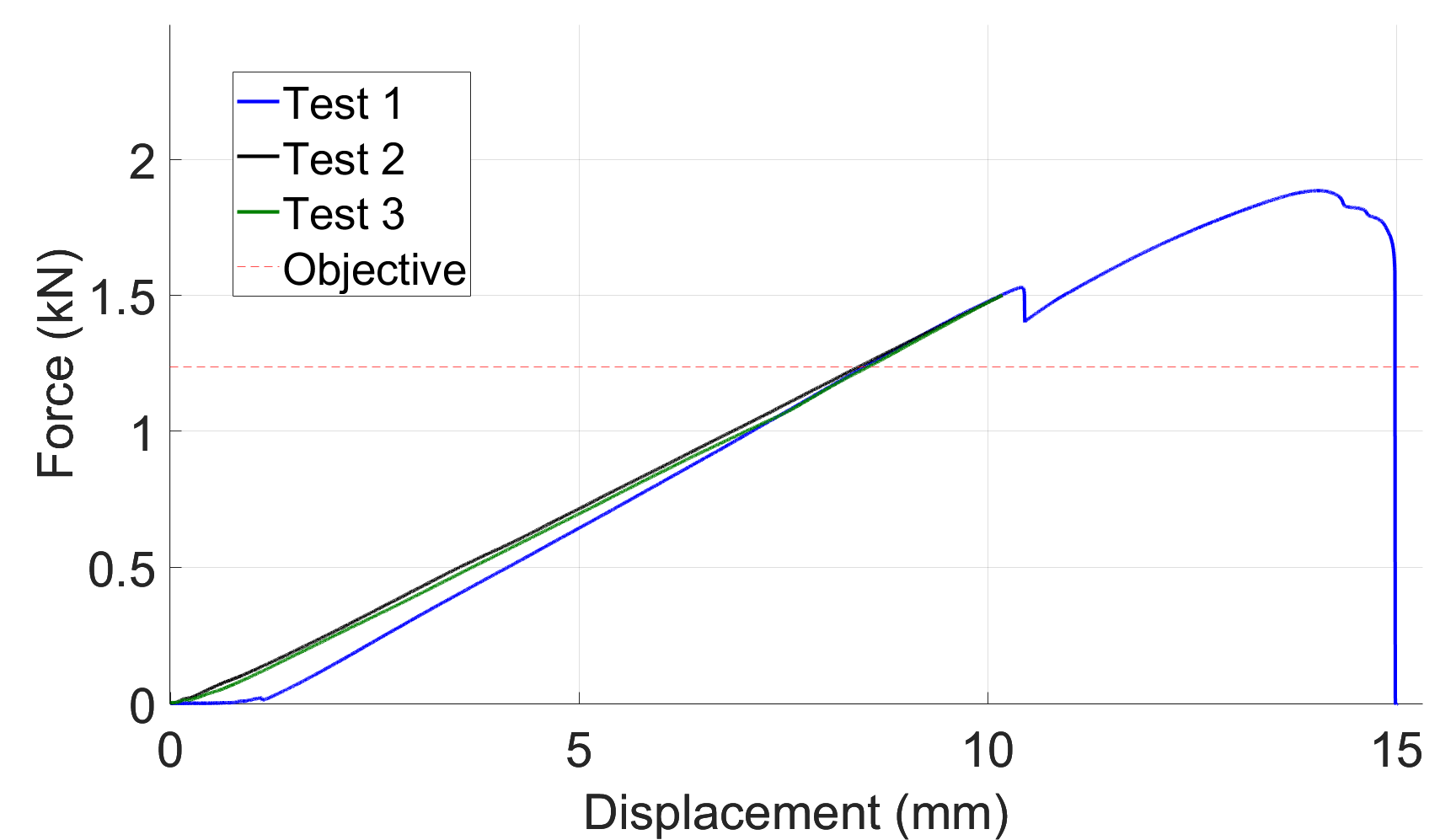

The device was developed following a user-centred design process, guided by interviews, a Product Specification Document (PSD) and iterative prototyping. A dual-material design incorporating Polyethylene Terephthalate Glycol (PETG) and neoprene was used to ensure strength and secure grip on varying bar diameters. Finite Element Analysis (FEA) and physical tensile testing verified structural integrity under a 1235 N load. A final 130º grip angle was selected based on proxy-user testing.

The device was shown to support forces 34% above the design load with a safety factor greater than 3 and a calculated fatigue resistance for more than 25,000 cycles. It securely gripped bars from 31.75–38 mm in diameter, weighed only 78 g and cost under £3.50 in materials. Proxy user testing confirmed its ergonomic design and ease of attachment/detachment.

Achieved a grade of 80.1

Ethical analysis, implementation plan, risk register and project timeline are available in the Planning Report.

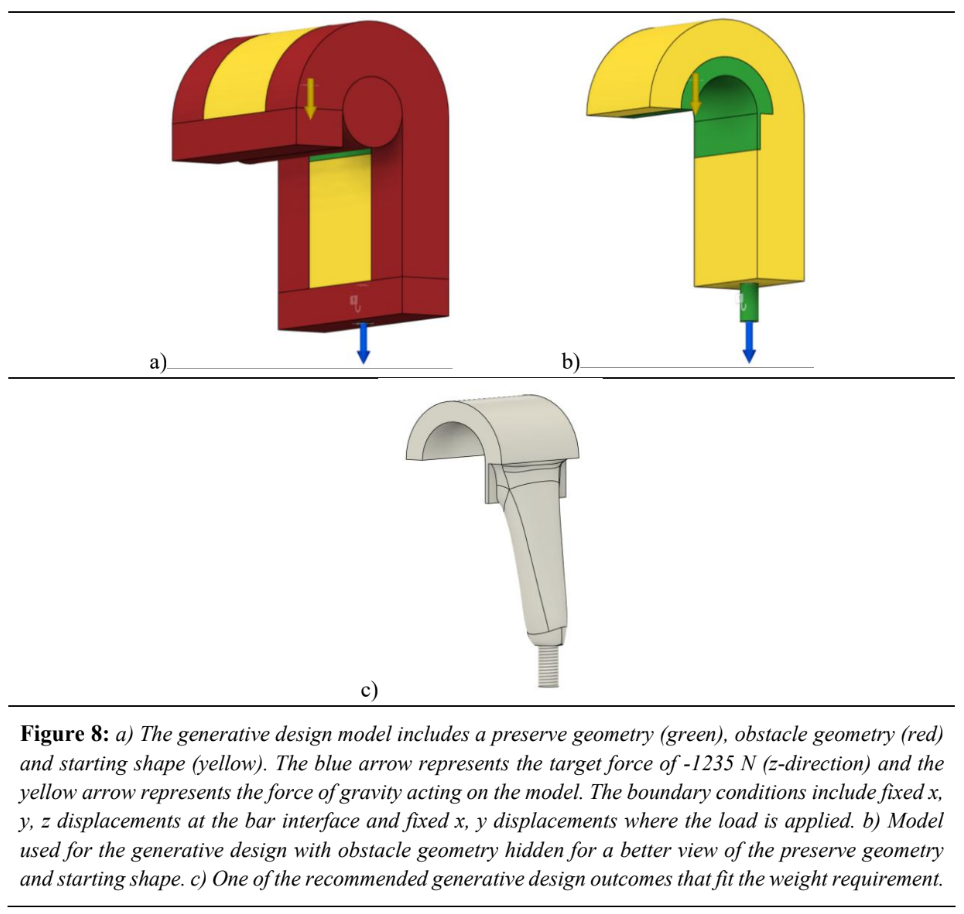

Generative design and topology optimisation were used to minimise the device’s mass whilst meeting the load-bearing requirement.

The design outputs guided later iterations, the material and manufacturing decisions.

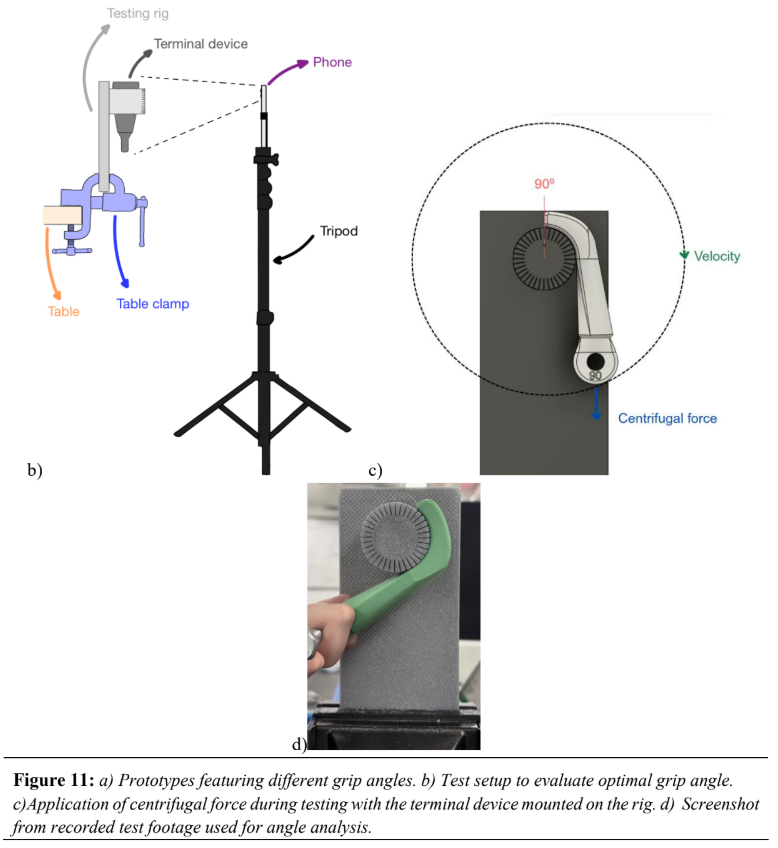

FEA results showed that a full 180º grip was not necessary for load bearing. However, selecting the appropriate angle was essential for safe attachment and ease of use.

The following test was carried out to identify the terminal device angle that provided both easy attachment/detachment and a secure grip during swinging:

1. A downward -Z force to simulate hanging.

2. A rotational centrifugal force in the ZX plane to simulate swinging.

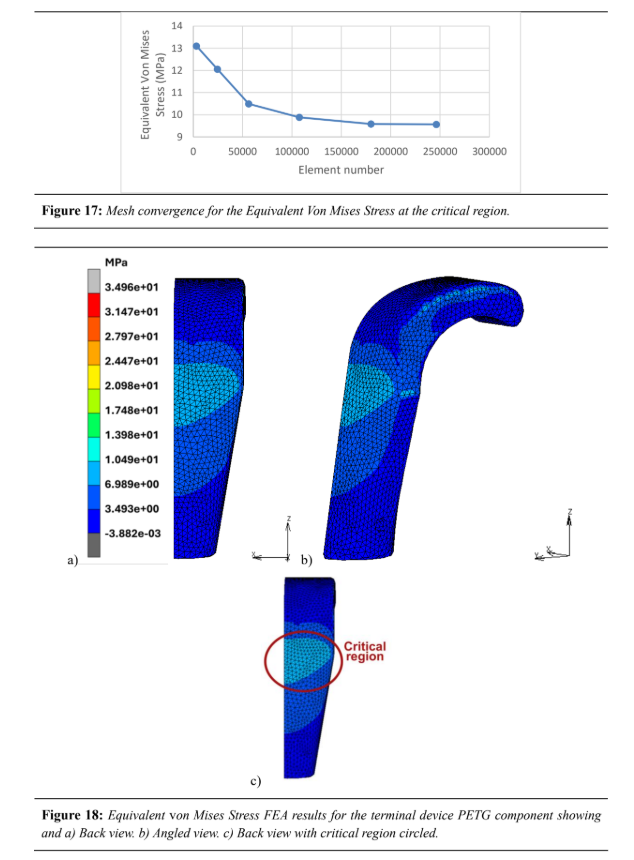

FEA was carried out to assess the load-bearing performance of the final terminal device design.

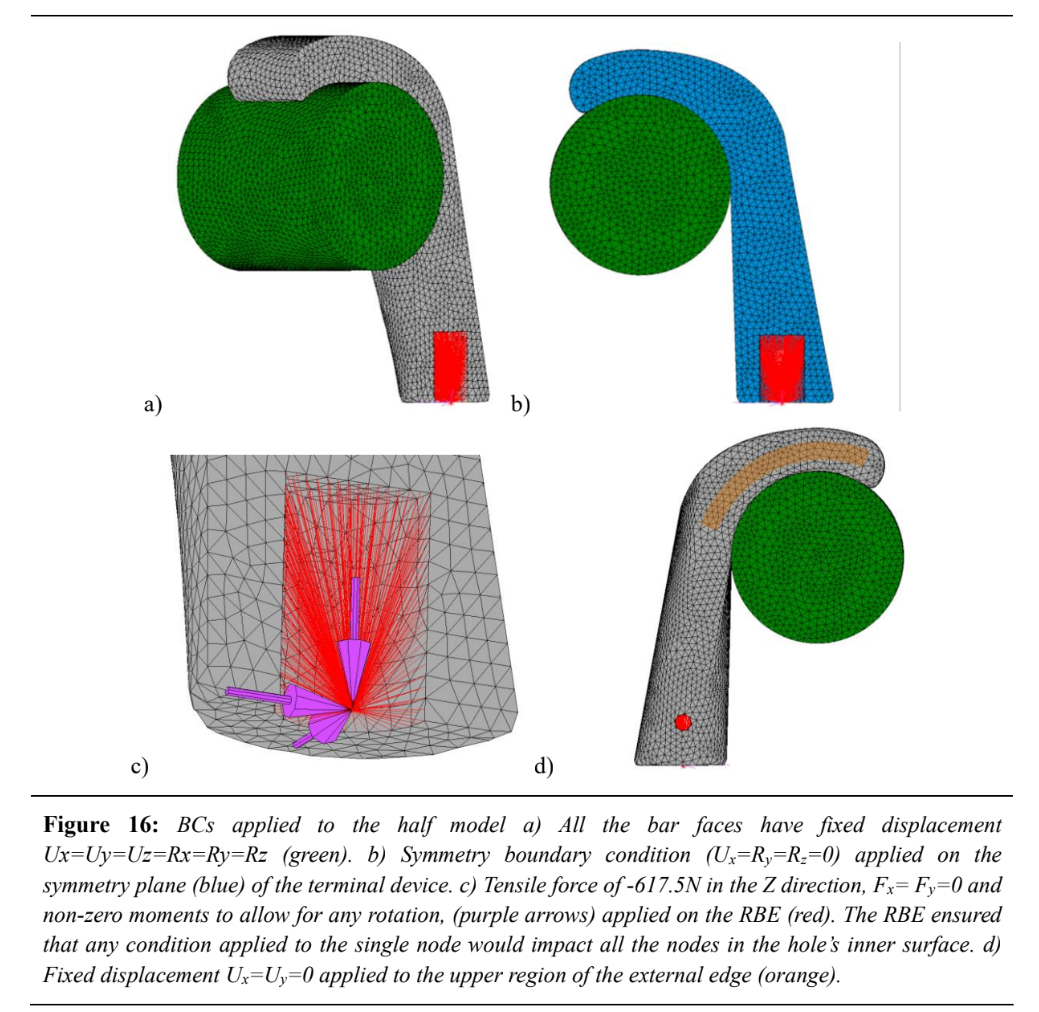

To reduce computational cost whilst maintaining accuracy, a half-model of the terminal device was used (after being validated against the full model) due to its geometric and load symmetry.

A mesh convergence study was carried out to verify results.

FEA assumes material isotropy and homogeneity which does not reflect the anisotropic nature of material extrusion and causes an overestimation of strength and stiffness.

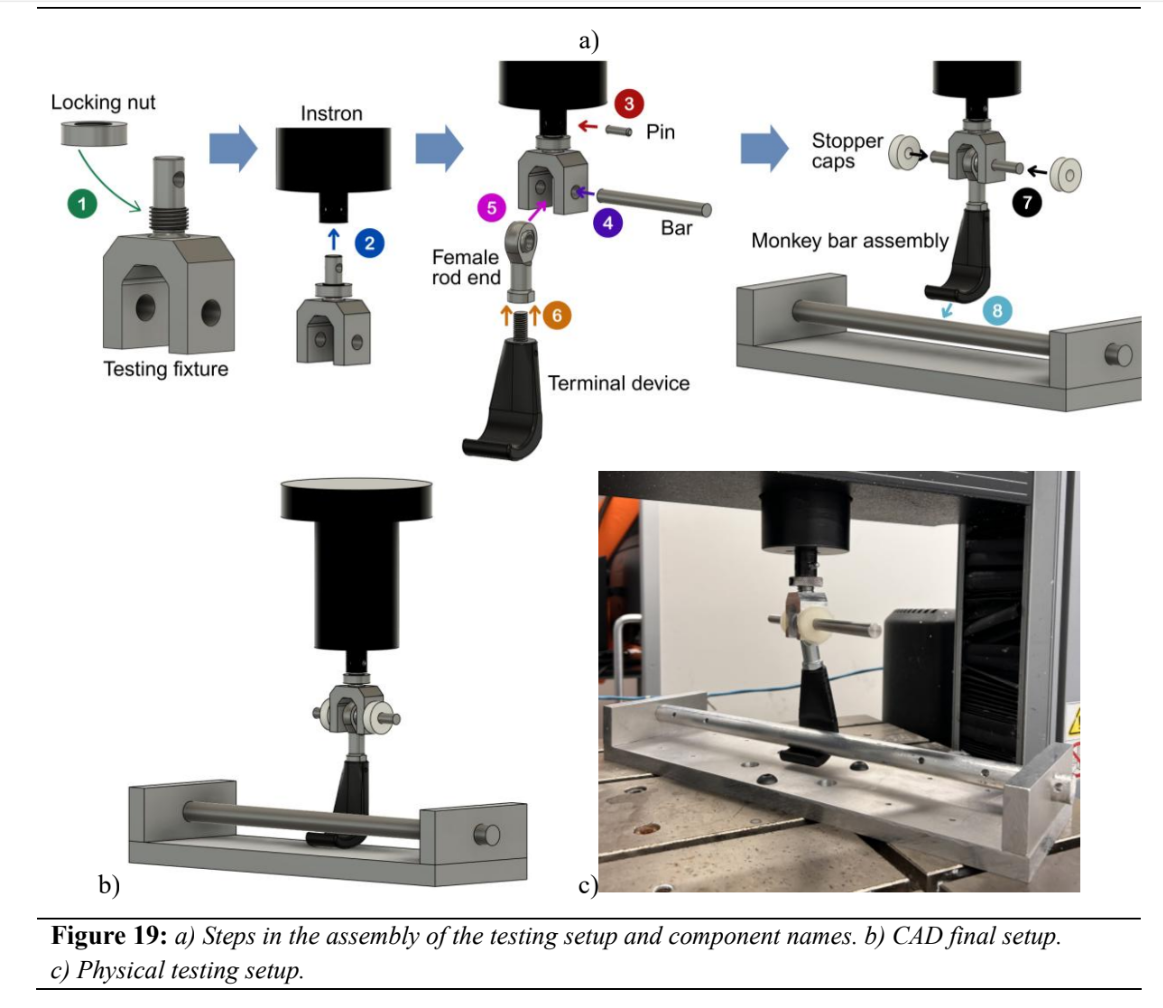

Therefore, physical tensile testing was carried out to verify the FEA results and confirm that the design can withstand the required load. A test